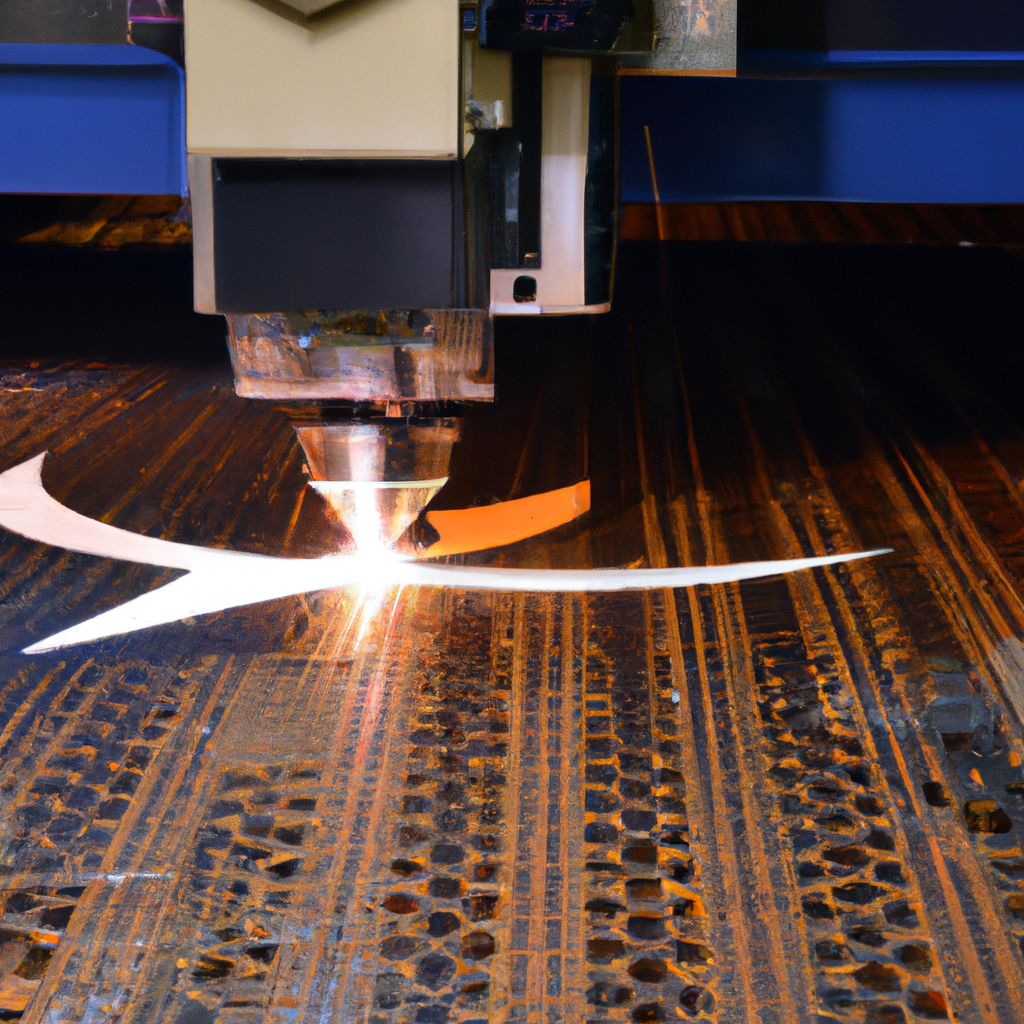

In recent years, CNC plasma cutting machines have gained immense popularity due to their efficiency and versatility. These machines utilize a high-velocity jet of ionized gas, known as plasma, to cut through electrically conductive materials such as steel, aluminium, and brass. By combining computer numerical control (CNC) technology with plasma cutting, manufacturers can achieve precise, intricate cuts with ease.

What is CNC Plasma Cutting?

CNC plasma cutting is a process that involves the use of a CNC machine to guide the cutting torch along a programmed path. The machine receives instructions from computer software, which determines the shape and dimensions of the desired cut. As the plasma torch moves along the material, it generates an electric arc between the electrode and the workpiece, creating a plasma jet that reaches temperatures of up to 30,000 degrees Fahrenheit. This intense heat melts and blows away the metal, resulting in a clean and accurate cut.

Advantages of CNC Plasma Cutting Machines

Speed and Precision

One of the key advantages of CNC plasma cutting machines is their exceptional speed and precision. These machines can cut through thick metal sheets at high speeds, significantly reducing production time compared to traditional cutting methods. The accuracy and repeatability of CNC plasma cutting ensure consistent quality across multiple cuts, making it an ideal choice for mass production.

Versatility and Flexibility

CNC plasma cutting machines offer unmatched versatility and flexibility. They can cut through a wide range of materials, including stainless steel, mild steel, aluminium, copper, and more. This makes them suitable for various industries, such as metal fabrication, automotive, aerospace, and even artistic applications. Additionally, CNC machines can create intricate and complex designs, allowing manufacturers to push the boundaries of their creativity.

Cost-Effectiveness

In addition to their speed and versatility, CNC plasma-cutting machines also provide cost-effectiveness. Compared to other cutting methods, such as laser cutting or waterjet cutting, plasma cutting is relatively more affordable. The initial investment cost for a CNC plasma cutting machine is lower, and the operational expenses, such as consumables and maintenance, are also comparatively economical. This makes CNC plasma cutting a viable option for small businesses and startups.

Applications of CNC Plasma Cutting Machines

CNC plasma cutting machines find applications in various industries, each benefiting from the unique capabilities they offer.

Metal Fabrication

Metal fabrication is one of the primary applications of CNC plasma cutting machines. Whether it’s cutting intricate designs, creating smooth edges, or producing precise shapes, these machines excel in fabricating metal components. From structural parts to decorative elements, CNC plasma cutting machines provide manufacturers with the ability to transform raw materials into finished products efficiently.

Automotive Industry

The automotive industry relies on CNC plasma-cutting machines for various purposes. These machines are used to cut components such as chassis, brackets, exhaust systems, and body panels. CNC plasma cutting ensures accurate and consistent cuts, resulting in parts that fit together seamlessly. The speed and precision of these machines contribute to increased productivity and reduced lead times in automotive manufacturing.

Art and Sculpture

CNC plasma cutting machines have made a significant impact on the art and sculpture world. Artists can now transform their visions into reality by using these machines to cut intricate shapes and designs from metal sheets. Whether it’s creating large-scale sculptures or delicate art pieces, CNC plasma cutting machines offer artists the ability to push the boundaries of their creativity and produce stunning works of art.

Construction and Architecture

CNC plasma cutting machines play a vital role in the construction and architecture industry. They are used to fabricate structural elements, such as beams, columns, and trusses, with high precision. These machines can cut complex shapes and contours, enabling architects and engineers to bring their innovative designs to life. CNC plasma cutting machines also contribute to faster construction processes, reducing project timelines significantly.

Factors to Consider When Choosing a CNC Plasma Cutting Machine

When selecting a CNC plasma cutting machine, several factors need to be taken into account to ensure the right fit for your specific requirements.

Cutting Capacity

The cutting capacity of a CNC plasma cutting machine determines the maximum thickness of the material it can cut. Different machines have varying cutting capacities, so it’s crucial to choose one that can handle the materials you work with regularly.

Power Source

CNC plasma cutting machines can be powered by either air or gas. Air plasma cutters are suitable for cutting thin materials, while gas plasma cutters are better suited for thick materials. Consider the types of materials you typically work with to determine the appropriate power source for your needs.

Software and Controls

The software and controls of a CNC plasma cutting machine play a crucial role in its usability and functionality. Look for machines with user-friendly interfaces, advanced nesting capabilities, and compatibility with various design software. A well-designed software and control system can streamline your workflow and improve overall productivity.

Maintenance and Support

Like any machinery, CNC plasma cutting machines require regular maintenance and occasional repairs. Before making a purchase, consider the availability of spare parts, customer support, and service centres. Opting for a machine from a reputable manufacturer ensures you have access to timely assistance whenever needed.

Future Trends in CNC Plasma Cutting

The field of CNC plasma cutting is continuously evolving, with several trends shaping its future. One notable trend is the integration of artificial intelligence (AI) and machine learning algorithms into CNC plasma cutting machines. This advancement allows the machines to learn and adapt to different cutting scenarios, enhancing their efficiency and accuracy. Additionally, advancements in plasma technology are making it possible to cut a wider range of materials and achieve even higher precision.

Conclusion

CNC plasma cutting machines have transformed the manufacturing and fabrication industry with their versatility and precision. From metal fabrication to automotive manufacturing, art, and construction, these machines offer numerous benefits and applications. By considering factors such as cutting capacity, power source, software, and maintenance, businesses can choose the right CNC plasma cutting machine to meet their specific needs. With future advancements on the horizon, CNC plasma cutting is poised to continue revolutionizing the way we create and shape various materials

…